DETERMINING TYPES OF SCISSOR LIFTS

• Decks are available in a variety of sizes, with smooth or checker plate tops. The top should be sized to properly and safely support the total load to be handled. Take care to specify if there is a special type of bottom on the load and if it is a rolling load such as hand trucks, pallet trucks or powered equipment.

• Capacity should be the total load to be handled including operators, wheeled equipment and container weight.

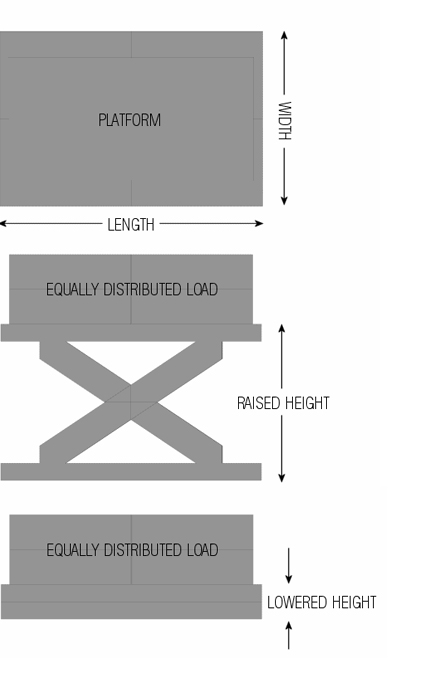

• Lowered Height is the desired height required for the operation of the equipment in the application it is intended for. The minimum lowered height available will be determined by the capacity, size and length of scissors chosen.

• Raised Height is the desired required to satisfy the application. The maximum raised height will be determined by the travel available from the length of scissors chosen. For higher lifts with shorter platforms, it is possible to use double scissor units and in certain applications triple scissors.

• Power Packs are the source of power and are sized according to the capacity and the speed of lift required. They are available in single phase and three phase units. Three phase offers the larger sizes for faster lift speeds and larger capacities. In hazardous areas, air motors are used. Always check power requirements and voltage available.

• Controls are the means to operate the lift. Choose the control (i.e.: Push Button, Foot Switch) that best meets the description of the operation. If the equipment is to interface with other machinery it will be necessary to discuss the control logic with the customer.

• Portable Units are made with wheels underneath or mounted on the outside of the frame. Wheels also increase the lowered height slightly and a Floor Lock may also be necessary.

• Safety Options are available in the form of electrically operated Toe Guards or Safety Curtains. In most cases it will be necessary to increase the deck size to accommodate the hardware of the safety device. Velocity Fuses are standard in Olympic cylinders which prevents the lifts from failing if a hydraulic line is severed.

• General Information about the operation will help Olympic recommend any additional options required. Always write a description of the operation (how it is suppose to work) and make a small sketch to illustrate how it should look.

SCISSOR LIFTS

• Decks are fabricated from C.S.A 40.21–44W smooth or checker plate steel varying from 114″ to 3/8″ thick depending on size, capacity and application. Some are reinforced with 3/8″ or 1/2″x4″ hollow structural steel tubing with 3″ and 4″ structural channel cross members again depending on the size, capacity and function.

• Base Frames are fabricated from C.S.A 40.21–44W 1/4″, 3/8″, or 1/2″ angle ranging in size from 3″x3″ up to 5″x7″.

• OMS Series Scissor Lifts are constructed from High Tensile Profile Cut Steel Plate.

• OML Series Scissor Lifts on all Double Scissors, Heavy Duty and Loading Dock lift tables, are constructed from C.S.A 40.21–50W High Tensile Hollow Structural Steel Tubing. The hollow structural sections provide the maximum possible stability for loading dock operation, heavy duty and double series applications.

• Power Packs have built in Overload Protection with an Integral Pressure Relief Valve. All power packs are built in the U.S.A. and parts are readily available.

• Motors are all rated for continuous duty cycle, in lieu of the intermittent duty cycle of 5 to 10 minutes, as a standard feature.

• Cylinder and Hinge Pins are ground and polished hard chromed steel.

• Pivot Points have the ‘Garlock’ Lifetime Self-Lubricating Aircraft Bushings.

• Cylinders are all hard chrome Steel with Velocity Safety Fuses as standard equipment.

***

For all other inquiries, please contact Olympic direct.